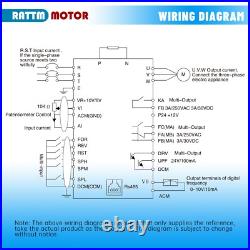

HY 4KW 220V Inverter VFD Frequency Drive Speed Control 5HP 18A. + 2m extension cables for CNC Milling Engraving Machine. A ustria, B elgium, B ulgaria, C zechRepublic, D enmark, E stonia, F inland, F rance, G ermany, G reece. H ungary, I reland, I taly, L atvia, L iechtenstein, L ithuania, L uxembourg, M onaco, N etherlands, P oland. P ortugal, R omania, S lovakia, S lovenia, S pain, S weden, UK. 220V 5HP 18A (Huan Yang Brand). 1 x 2M Extension cable/control panel box. 1 x English user manual. 100% Brand New and High Qulaity!! 1 Input Voltage: 220V (+/-15%). 2 Output Voltage: 220V (+/-15%). 3 Input Frequency: 48-60Hz. 4 Output Frequency: 0-400Hz. 5 Input Phase: 1 phase or 3 phase. 6 Output Phase: 3 phase. 7 Output Current: 18A. 9Product dimensions: 5.98×6.88×8.66 inch/152x175x220mm. 11Weight: 5 LB. 1PID control; advanced calculus PID closed-loop arithmetic. 2Easy PLC function can realize 16 legs of speed and inverter control function. 3Low output ratting torque 0.5HZ-150%. 4Carrier adjustable by 16KHZ. 5AVR technique, for ensuring the inverter load capability. 6Various control technique by both synchronization and non-synchronization. 7A potentiometer can be used to adjust to the rotation speed you want. 8RS485 communication port, adopting standard international MODBUS main circuit control. 9Supports external potentiometer control, pls connect the “FOR” and “DCM” terminals, than set PD001=1. 10 Supports mach3 function and RS-485 communication. VFD’s U= Spindle’s 1. VFD’s V= Spindle’s 2. VFD’s W= Spindle’s 3. Connect any “R” & “T” of the inverter to “220VAC” input wire. If your motor’s speed is not 400hz 24000rpm, you need to change the drive parameters, then connect 3 phase motor, before you change the parameters, you need Factory Reset, then change PD013 to 8, then you can change the parameters. Progressively increase data or function codes. Progressively decrease data or function codes. Enter menus step-by-step, save setting parameters. Mainly used to switch monitoring state, exit to previous menu. Switch monitoring parameters at monitoring state, at secondary menu, move data box to process editing position. FOR / REV switch. The inverter is equipped with a DC cooling fan, which has low noise and large air volume during operation, which is very conducive to heat dissipation and improves the stability of the product at work. With overload, fuse broken-motor stops, over-voltage, low-voltage, restarted by frequency track after instantaneous stop, electronic circuit, over-heat, running, direct start after power on, fault reset, parameter lock PID, ect. Our inverter is running. 400Hz 3 phase 220V. If your 3 phase motor is 400Hz, you can check the default setting and run it directly. If your 3 phase 220V motor is. Please refer to the following settings. To restore factory settings first. Widely used in 3 phase Spindle motor, CNC Router, CNC machine, milling machine, drilling machine, wingding machine, extruder, slitter, mixer, winder, compressor, ventilator, pump, grinder, conveyor, elevator, centrifuger and other speed control machines. Problem&Feedback Please give us the opportunity to resolve any problem when you have, we concern your problem and we will try our best to resolve it. Item must be in it’s original condition and no physical damage.