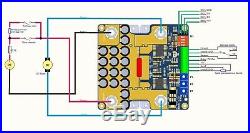

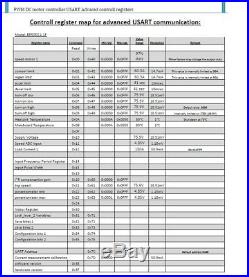

We have several type of DC motor PWM controllers! Simple forward or reversible version. Up to 300A and 200V with programmable USART and other useful functions and more.. ^^^Donload the datasheet with this link^^^. This is a very compact and easy to use high efficiency FULL-BRIDGE PWM speed controller with forward/ reverse function for any brushed motor. Like: trolley, outboard, electric bicycle, go-cart and any other application. Just connect your battery and your motor to the M6 screw input set the maximum current with the small blue trimmer potentiometer on the board and you are ready do use the system. Set the speed with the speed potentiometer or your throttle change forward/resevre direction with the switch or use your own small signal switch. Advantages against other motor PWM controller. Easy to setup: 1. Connect the speed potentiometer and direction switch 2. Connect the supply and the motor 3. Set the current limit 4. Turn it on and use. Built in 4PCS ultra low resistance 3mOhm powerfull MOSFETs with these the 50A continuous current is true 50A continuous current. 100A limited peak current for a short time. Normal current limit protection is adjustable between 0-50A many people dont know but this is very important for the motor controllers a with other controllers you can see there are no adjustable current limit and a fuse is too slow to protect the controller if a peak load or switching a direction occurs. When you start the motor the starting surrent can be 2-5x as the nominal current. When you change direction the current can be 10-15x larger than the normal current. This controller can limit this fast changes. Trust me and always choose a controller which has current limit protection! (it is usefull for go-karts, and other vechiles). Full-Bridge topolgy allow you to change the direction of the rotation electricaly. (H-bridge) (Other controllers has relays which producing a lot of heat). You don’t need large current forward reverse switch. The board change the rotation electrically. 16pcs 470uF capacitor (chinese controllers only has 2-4pcs which is very few for a 50-60A controller). Connection with high current M6 screws you can use strong high current ring terminals as a professional high current connection. (no weak lug connectors like chinese controllers). 4 programable controlling modes with the red switch. 0-5V analoge input + direction switch. Analog joystick mode (potentiometer in middle stop turn left or right raise the speed in forward or reverse direction). PWM input + direction signal (for example a PWM signal from ARM, PIC, Arduino or PLC). RC receiver PWM signal. You don’t have to use the potentiometer to controll the speed. You can use PLC output or other controll signal or PWM signal to controll the speed and the direction. Adjustable 0-20sec acceleration limit it is very useful for gokarts and other kind of electric vechiles if you want to limit the acceleration. Universal supply voltage between 10-50V DC. Dimensions: 140 x 100 x 35 mm / 5,6″x 4″ x 1,4. You can choose between 6 operation modes with the red DIP switch on the PCB board. Normal potentiometer mode 0-5V 0-97% output voltage. Magnetic hall throttle mode (0.5-4,5V input) or programable input voltage like 1-3V or anything you want. Simple PWM signal (0-95%) from arduino or a RC receiver. RC receiver PWM input 1,5ms +/-1ms. RS232 controll with simple commands recommended for beginner programmers for example Arduino. RS485 advanced controll for precise industrial controll. With the optically isolated connection and CRC protected communication you can communicate with the device and get access for the all controll registers. Adjustable and saveable parameters with RS232/RS485 read/write commands. Current limit/regenerative current limit. Turn ON/OFF minimum and turn ON/OFF maximum voltage levels for example turn off the unit at low battery voltage. Heatsink and Motherboard temperatures. Potentiometer input voltage (you can use this input for an analoge measurement input if you are controlling the speed with RS232/485 commands). Input frequency on PWM input. Input duty on PWM input. I x R compensation (this if for speed regulation compensation the load drop voltage). Supply compensation (maximum speed limit) this can be very usefull in more cases. As you give a maximum reference voltage (maximum RPM) what the output can be with the maximum gas setting. This value becomes a reference voltage and archive perfect supply voltage compensation. This means if your supply voltage drops of raise your motor PRM remains the same. Using the supply compensation and the I x R compensation together you can archive perfect speed regulation without any closed loop feedback and no tachogenerator is needed. Adjustable RS485 address controlling more controllers on one line. For more information and how to use the RS232/485 communication please read the datasheet with the controll registers. Please send a message if you. Have any question special request or something. We are electrical engineers. If you need bulk prices or more than one even 2 pieces we will give the best prices. So why choose this controller? They are great until you put a large load to they output. That controllers don’t have supply filtering what is very important! Without it the most of the chinese controller regularly burning down. They haven’t got proper flyback diode against the motor inductive current! The most of them don’t have any current limit function which is very important by a motor. This controller is a current limited speed controller for any brushed DC motor with great LOW ESR capacitor supply filtering and a syncronous flyback diode! How can you controll the motor speed with this controller? With the current limit potentiometer you can very fine adjust the current what the motor can maximum consumes. For example, you have 500W 24V DC motor. Your motor nominal current is 20A. Than you adjust the current limit to 25-30A. After them your motor and PWM driver is fully protected against the burning down and over load. Additional protection is the temperature protection. The controller measure the temperature of heatsink. If that exceed the maximum than the controller shutting down. You can easily control the motor speed between 0-95% with the motor speed controller potentiometer which is connected to the potentiometer terminal. You can use as long potentiometer cable as you want. So you don’t have to mount the PWM and the potentiometer juxtaposed. Worldwide: mainly 8-12 days. Please follow us because other type of new motor controllers will be released soon! The item “100A 50V 12V 24V Reversible DC motor Speed Controller PWM waterproof box arduino” is in sale since Saturday, September 9, 2017. This item is in the category “Business & Industrial\Industrial Automation & Motion Controls\Drives & Starters\Drives & Motor Controls\Speed Controls”. The seller is “powersolutions_hu” and is located in Dunaszentgyörgy. This item can be shipped worldwide.

- MPN: Does Not Apply

- Brand: Unbranded